Fire safety has moved from being optional to essential in modern construction and interior design. Materials are expected to perform well, look good, and protect lives at the same time. This is where Fire Retardant Plywood becomes a practical and trusted choice. We focus on solutions that reduce fire risk, slow flame spread, and maintain structural strength. This article presents a clear, connected view of how this plywood fits into real projects, how it aligns with standards, and why it delivers long-term value.

Comprehending Wood Panels That Resist Fire

Ordinary wood products fail quickly in high-risk scenarios. That equation is altered by treated wood panels. These panels are designed to prevent flames from spreading across their surface and to withstand ignition. They are made from specific hardwood or softwood veneers that have been treated with chemicals that prevent fire and glued with specialty resins.

As a result, consistent performance under heat exposure is achieved without sacrificing durability, workability, or finish. Fire-retardant plywood increases safety throughout the building while blending in seamlessly with conventional building techniques.

The Operation of Fire-Retardant Treatment

The plywood core is deeply penetrated by the treatment procedure. Heat causes fire-inhibiting substances to react, generating non-flammable gases that lower the amount of oxygen available. A layer of protective char develops on the surface at the same time. This layer limits the spread of flames and acts as insulation for the inner layers.

Because the panels don't promote quick combustion, residents have more time to flee, and firefighters can respond efficiently. Daily wear and variations in humidity don't affect the performance.

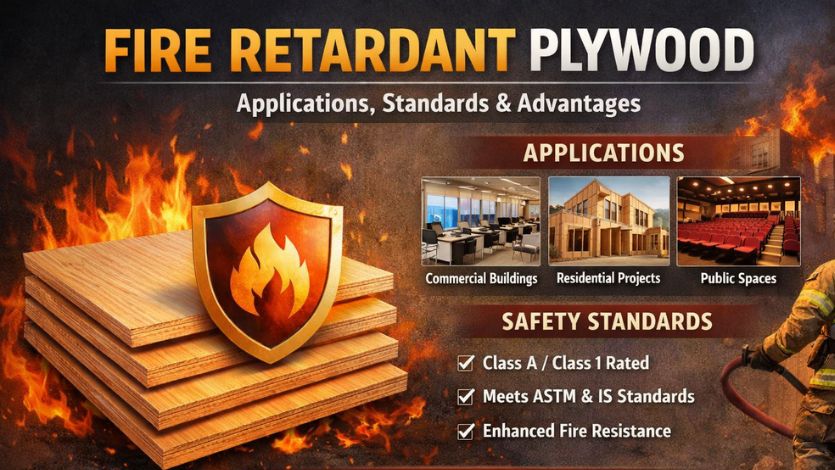

Important Uses in Actual Spaces

Fire retardant plywood is becoming more and more used in commercial, industrial, and residential settings. One of its greatest benefits is its adaptability. It is utilized in kitchens, stairwells, lofts, wardrobes, and wall panelling in residences. Heat sources and electrical fixtures are prevalent in these places.

It promotes safer interiors in business buildings. It is used in offices for workstations, conference rooms, ceilings, and walls. Hotels use it for function halls, guest rooms, and hallways where fire safety is strictly enforced.

Schools, hospitals, airports, and shopping centers are examples of public structures that rely on materials that satisfy safety regulations without sacrificing design. This plywood is ideal for meeting that need.

Standards and Compliance That Are Important

Safety materials must adhere to established standards. This plywood is evaluated in accordance with both national and international fire safety regulations. These tests gauge the growth of smoke, heat emission, and flame spread.

Suitability for regional building codes is guaranteed by adherence to Indian Standards. Numerous goods that are utilized in major infrastructure projects also adhere to international standards. This makes them reliable for architects, contractors, and safety auditors.

Projects pass inspections with ease when certified fire-retardant plywood is used. It reduces legal risk and builds trust with end users. Standards are not paperwork. They are proof of performance under pressure.

Benefits of Performance Beyond Safety

The main advantage is fire resistance, but there are other advantages as well. Strong structural stability is provided by this plywood. It is resistant to warping in hot or humid conditions. It is hence dependable for extended use.

All common finishes are supported. Its surface is good for laminate, veneer, paint, and polish. Designers don't have to sacrifice aesthetics.

Its load-bearing strength is good. Its fixtures and furniture continue to be robust and long-lasting.

It's easy to maintain. After installation, it doesn't need any extra attention. As a result, lifetime costs are reduced and overall value is increased.

For projects that require both performance and peace of mind, using fire-retardant plywood is a wise choice.