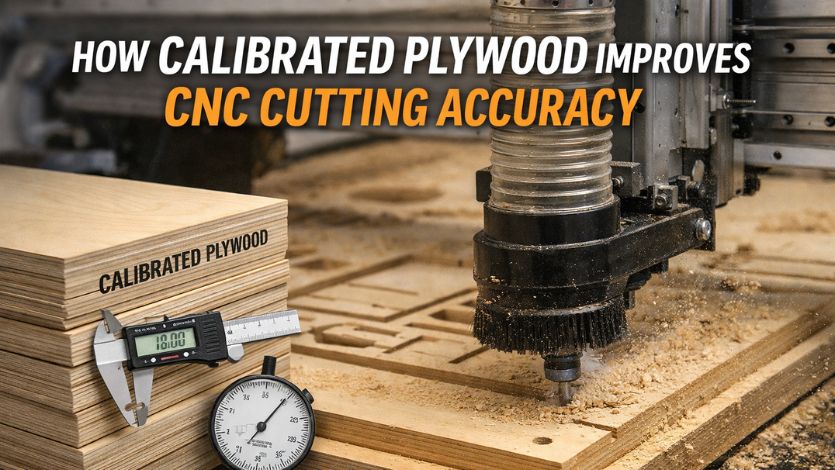

When CNC machines do high-speed cutting, every millimetre is important. Even little differences in board thickness can disrupt alignment, alter toolpaths, and result in noticeable irregularities in the finished product. This is where calibrated plywood has a distinct advantage. Its uniform thickness, smooth surface, and designed stability make it the best material for current CNC operations.

Our primary focus is on how calibrated plywood immediately increases CNC accuracy, cutting efficiency, and high-quality finishing in furniture, interior design, modular kitchens, industrial fabrication, and other applications.

Why Thickness Uniformity is Important for CNC Cutting

CNC cutting requires predictable material behaviour. If a board's thickness changes, the CNC bit cuts deeper in some places and shallower in others. This leads to uneven grooves, poor joinery, and misaligned components.Calibrated plywood avoids this possibility. Each sheet is precision sanded and machine calibrated to ensure equal thickness throughout the whole surface. This constancy guarantees clean cuts, consistent toolpath movement, and perfect results.

Key benefits include:

- Ensuring consistent tool interaction with the surface

- Precise depth control when cutting and grooving

- Reduced rework because there are fewer dimensional errors

- Improved alignment of several sections cut from the same sheet

Uniformity is the foundation of CNC accuracy, and calibrated plywood offers it with consistency.

Smooth surface improves tool life and finish quality

A CNC cutter interacts with a surface thousands of times per second. Any lumps, gaps, or surface differences lead to vibration, tool wear, and rough edge finishes.

Calibrated plywood has an unusually smooth surface. This ensures:

- Low resistance to the cutting tool.

- Minimal chipping on edges.

- Clean engravings and patterns

- Faster processing due to stable movement.

Manufacturers benefit from longer tool life and more consistent cutting cycles as a result of the enhanced surface.

Dimensional stability is important in CNC machining

CNC projects frequently include tight-fitting joints and multi-part assemblies. Even minor expansion, bending, or warping of the material jeopardizes the end product.

Calibrated plywood has high dimensional stability due to its layered composition. It resists

- Warping

- Core gaps

- Thickness and swelling

- Internal delamination

This stability guarantees that CNC-cut pieces fit properly in cabinetry, panelling, or custom components. Industries that rely on precision rely on calibrated plywood to keep its shape even when humidity and temperature fluctuate.

Improved Toolpath Accuracy via Reliable Board Structure

A CNC machine takes a predetermined digital path. However, if the material beneath is inconsistent, the end outcome will diverge from the concept.

A stable, void-free core is critical.

Calibrated plywood is constructed from selected hardwood or high-quality softwood veneers that are glued under high pressure. This ensures:

- A dense and homogenous core.

- There are no cavities that would cause tool drops or vibration.

- Smooth internal bonding allows for consistent cutting.

CNC machines with sufficient structural integrity may execute elaborate detailing, engraving, lattice work, edge profiling, and 3D carving more clearly and precisely.

Improved Strength-to-Weight Ratio for Complex CNC Work

Certain CNC applications necessitate thinner sheets with high load-bearing capability. Standard plywood may not always have the necessary strength, particularly in elaborate work such as Jali cutting or perforated designs.

Calibrated plywood has a balanced strength-to-weight ratio, making it suitable for:

- Decorative panels

- Furniture components are lightweight.

- Modular systems.

- Architectural cut-outs.

- Vehicle interiors

Its strength guarantees that even delicate CNC patterns maintain structural integrity.

Higher Productivity and Reduced Material Wastage

CNC workshops strive for optimum efficiency. Material difficulties slow down cutting, require more maintenance, and result in costly waste.

Manufacturers who use calibrated plywood experience:

- Fewer rejected pieces

- Reduced blade wear

- Faster machining cycles

- Optimum material utilisation

- Reduced operational costs.

Because each sheet performs consistently, CNC operators can complete huge batch projects with consistent results.

Applications in which calibrated plywood maximizes CNC output

The industries that profit the most from CNC precision rely significantly on calibrated plywood. Its consistency and stability make it suitable for:

- Kitchen components are modular.

- Wardrobe shutters

- Furniture panels

- Designs engraved on the walls

- Jali and CNC cut dividers.

Why Manufacturers Choose Calibrated Plywood Over Standard Plywood for CNC

Thickness and internal bonding quality vary among standard plywood. This inconsistency causes serious complications during CNC routing. Calibrated plywood, on the other hand, is subjected to stringent quality control and machine calibration.

Why professionals prefer it:

- Accurate tolerance for thickness

- High mechanical strength

- Faces are smooth and defect-free.

- Better bonding between veneers.

- Reliable performance on CNC machines.

These characteristics make calibrated plywood the preferred material for businesses that require precision and polish.

Conclusion

Calibrated plywood improves CNC cutting accuracy significantly. Its homogeneous thickness, robust structure, and smooth surface contribute to faultless cuts, greater dimensional control, and increased production. Whether you're working on furniture, interiors, paneling, or artistic CNC designs, calibrated plywood guarantees consistent and dependable results every time.

If you require premium calibrated plywood with high precision and dependability for CNC operations, contact GMG Plywood today for exceptional quality and long-lasting performance.