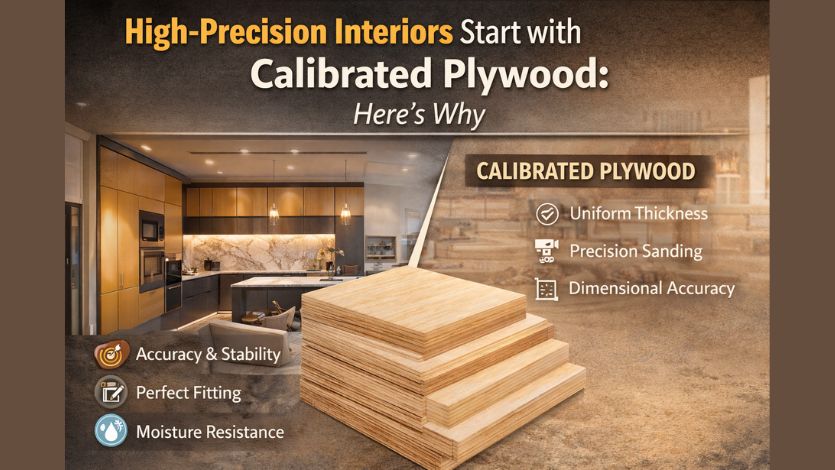

When it comes to creating beautiful and structurally solid interiors, professionals rely on Calibrated Plywood as their base. Calibrated Plywood's precision and solidity are invaluable whether designing premium furniture, modular kitchens, or commercial areas. Let me explain why this material has become the gold standard in modern interior design.

What sets calibrated plywood apart

Calibrated Plywood is made with superior technology to ensure equal thickness across each sheet. Unlike conventional plywood, which frequently changes in dimension, calibrated versions go through a two-stage calibration process that employs high-end sanders and press machines. This ensures a smooth, flat surface, which is great for precise work.

The truth is that when your base material is precise to the millimetre, your finished product looks and feels immaculate. Cabinet doors fit flawlessly, laminates attach smoothly, and panels match perfectly. It's the secret behind the intricate workmanship found in high-end homes.

Uniform thickness indicates flawless finishes

In interior design, even a millimeter can alter the outcome. Uneven plywood can create surface warping, misaligned edges, and exposed joints, all of which detract from the aesthetics of your design. Calibrated Plywood eliminates these issues from the start.

Every panel is sanded to the same thickness, ensuring a precise connection with veneers, laminates, and paints. This homogeneity lowers the need for additional sanding or correction on-site, saving both labor and time.

Strong and Durable

Calibrated Plywood is designed to be both precise and long-lasting. It is made of high-quality hardwood veneers that have been bonded with strong adhesives under controlled temperature and pressure to provide remarkable strength and load-bearing capacity.

It is resistant to warping, cracking, and swelling, even in humid environments. That is why architects and builders prefer it for closets, kitchen cabinets, office furniture, and wall paneling, where both appearance and durability are important.

Ideal for modular and machine-cut designs

Cutting and shaping in modern modular furniture manufacture is done with CNC equipment. Here's where Calibrated Plywood shines. Its smooth surface and regular density make it excellent for machine use. You always get smooth cuts, clean edges, and well-fitted joints.

This consistency also reduces production waste. When panels are uniform, every item fits exactly, increasing efficiency and decreasing rework.

Enhanced aesthetic appeal

Calibrated Plywood's smooth, defect-free surface makes for perfect finishing. Whether you pick laminates, veneers, or paint, the end product is always polished and luxurious. The material highlights the inherent beauty of your surface finish, resulting in interiors that are as visually appealing as they are functional.

Furthermore, its resilience ensures that your designs seem new for years without bubbling or surface flaws.

A better investment for long-term projects

Calibrated Plywood is slightly more expensive than normal plywood, but it pays for itself in the long term. Its precision decreases installation challenges, prevents material waste, and shortens completion time. As a result, the workflow runs more smoothly, and there are fewer complaints after installation.

For contractors and builders, this implies increased client satisfaction and a stronger reputation. For homeowners, it means having beautiful interiors that last longer without requiring frequent repairs.

Why Use GMG Plywood for Calibrated Plywood?

At GMG Plywood, we are integrating accurate production and quality that cannot be compromised. The Calibrated Plywood that we manufacture encompasses the use of modern machinery and raw materials of good quality to ensure quality output in all applications.

We know that interiors are not mere places, but personal statements of style and comfort. This is why we make our plywood to work under pressure, to support the pressures of the environment, and provide aesthetic appeal to your interior. As a designer, architect, or homeowner, GMG Calibrated Plywood gives you the ability to realize long-term perfection.

FAQs About Calibrated Plywood

1. What is Calibrated Plywood used for?

Calibrated Plywood is mainly used in modular furniture, kitchens, wardrobes, and decorative interiors where precision and smooth surface finishing are essential.

2. Is Calibrated Plywood better than regular plywood?

Yes. It offers uniform thickness, better bonding with laminates, improved machine performance, and long-lasting durability compared to regular plywood.

3. Can Calibrated Plywood be used in damp areas?

Absolutely, if you choose a moisture-resistant or BWP-grade variant. These are designed to perform well even in humid or wet environments.

4. Is it eco-friendly?

Reputed manufacturers like GMG Plywood use responsibly sourced wood and low-emission adhesives, making it an environmentally responsible choice.

5. Why does precision matter in plywood?

Precision ensures perfect alignment, clean finishes, and minimal wastage—key elements of high-quality interior work.

Final thoughts

Precision, performance, and perfection all start with calibrated plywood. If you want interiors that appear perfect and last for years, this is the best foundation to use. Choose GMG Plywood for dependable quality and exceptional craftsmanship when creating environments that represent greatness.