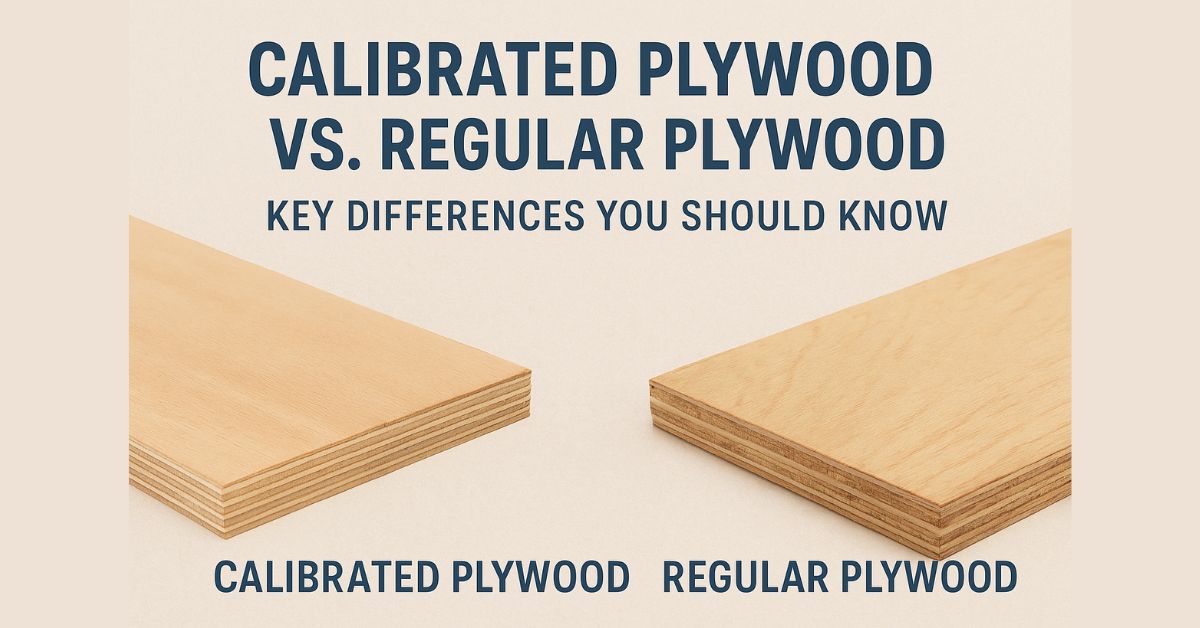

When deciding on the appropriate plywood for furniture, flooring, or other applications in the industrial sector, the decision about whether to use Calibrated Plywood or a normal plywood product is typically one of the most discussed topics. They both have multiple applications in the woodworking sector but vary widely in factors including precision, performance, and durability. Knowing these differences allows professionals (and homeowners) to make better project decisions for long-lasting high-quality outcomes.

What is Calibrated Plywood?

Calibrated Plywood is a premium engineered wood product that is produced with precision equipment to ensure a consistent thickness throughout the sheet. The veneer layers are carefully selected, assembled, pressed, and calibrated to standard dimensions, within a tolerance of ±0.1 mm, using modern sanding methods.

Calibrated Plywood is recommended for any modular furniture, kitchen cabinets, etc., that requires an accurate fit and a smooth finish. Its consistency and tight tolerances result in a material with very little fluctuation, meaning no inconsistent or undesirable wood grain appearance that is seen in plywood. As a bonus, it is perfect for automatic and CNC cutting.

How Does Regular Plywood Differ

Even though regular plywood is commonly used, it is not produced in the same manner as calibrated plywood, meaning it would not be produced with the same level of accuracy. The veneers are glued together and pressed, causing small thickness variations throughout the sheet. Whereas it is fine for most general building or for areas where high precision is not necessary, it does not provide the consistency needed for fine furniture or intricate work.

These small variations could inevitably result in gaps, uneven joints, or misalignments, which are extremely easy to avoid with Calibrated Plywood.

The Advantages of Calibrated Plywood

1. Uniform Thickness

The greatest advantage of Calibrated Plywood is its precisely uniform thickness. This results in a smooth, balanced surface, which is essential for modern furniture manufacture and modular layouts. Every panel fits perfectly with no need for manual modifications.

2. A smooth surface for finishing.

Calibrated Plywood makes a great substrate for laminates, veneers, and paints because of its constant thickness and superior surface quality. You save both time and material when finishing work, resulting in a cleaner appearance and greater aesthetic appeal.

3. Ideal for precision cutting.

When using regular plywood in automated machinery such as CNC routers, discrepancies can occur. In contrast, calibrated plywood ensures that each piece is cut with precise accuracy, eliminating waste and increasing industrial productivity.

4. Improved strength and stability.

Calibrated Plywood's balanced structure and high-quality bonding provide increased strength, durability, and load-bearing capacity. It is less prone to warping, bending, and delamination even when stressed or exposed to moisture.

5. Time and Cost Efficiency

While Calibrated Plywood is slightly more expensive initially, it saves significant time and money during manufacture and installation. The smooth finish requires less sanding and polishing, and the uniform thickness reduces manufacturing rejection rates.

Application of Calibrated Plywood

Calibrated Plywood is suited for a variety of applications due to its precision and durability.

Modular furniture ensures proper fitting and joint alignment.

Kitchen Cabinets and Wardrobes: Provides a smooth and consistent finish for laminate surfaces.

Flooring and paneling: Provides a sturdy, secure foundation for decorative surfacing.

Partitions and ceilings: Keeps dimensions accurate and edges tidy.

CNC-based designs: Perfect for laser cutting and precise detailing.

Calibrated Plywood outperforms ordinary plywood in all of these applications because of its precise calibration and consistent strength.

Why Builders and Architects Prefer Calibrated Plywood

Precision is a necessity in contemporary architecture and interior design, not just an option. The availability of engineered, calibrated plywood permits architects and designers to achieve cleaner lines, sharper finishes, and better alignment. In addition, the structural stability of professionally calibrated plywood guarantees that the furniture retains its shape or form for years without drooping or loosening.

While standard plywood would still work for basic applications, when it comes to durability and quality of product, calibrated plywood is the best option.

Durability and Long-Term Performance

A defining quality of Calibrated Plywood is its capacity to hold its form and strength over time. It features multiple layers glued together under high pressure with outstanding adhesives, making it resistant to cracking and bending and to termites.

On the other hand, regular plywood often shows signs of delamination or bowing over extended periods of exposure to moisture and temperature changes. This is why most professionals use Calibrated Plywood for projects that require both visual beauty and durability.

Conclusion: The Smarter Choice for Long-Lasting Results

When precision, durability, and appearance are paramount, Calibrated Plywood is by far the best choice. Uniform thickness, smooth finish, and strength make Calibrated Plywood ideal for modular furniture, interiors, and architectural projects where perfection is required.

GMG PLYWOOD is proud to manufacture Calibrated Plywood that meets the highest standards in the industry. Every sheet is subject to rigorous quality testing to ensure its accuracy, smooth surface, and long-lasting strength.

If you are in need of reliable, standard, and premium quality, and consider Calibrated Plywood, contact GMG PLYWOOD today, and experience the difference precision makes.